The Ecodelta, the first Dutch dredger on LNG, has been used as a business case to study the feasibility of carbon capture on board. With the infrastructure to handle future marine fuels created from hydrogen already in place, LNG-powered ships are well suited to create a closed carbon loop in the future hydrogen economy.

The Ecodelta was designed by Conoship International for dredging company Van der Kamp. This company needed the design for the tender to perform the maintenance of the Port of Rotterdam until 2023. The Port of Rotterdam wanted a more sustainable dredger to perform this task, hence the choice for LNG.

Ready for Upcoming Emission Regulations

Conoship provided the design, basic and detailed engineering, and system integration services for this vessel, which is also fitted with special equipment for cleaning up accidental oil-spills in the area it serves. The optimised hull for minimum fuel consumption, tailored to the bunker interval, and the integration of an LNG tank in the design are the most important innovations.

By applying LNG technology, the vessel already meets the upcoming regulations for emission reduction that will come into force in 2020. The usage of LNG reduces the emissions of CO2 by up to twenty per cent and NOX by up to 85 per cent. In addition, SOX is reduced to zero.

Details of the Ecodelta

- Design & engineering: Conoship International BV

- Client: Bagger- en Aannemingsmaatschappij Van der Kamp BV

- Built by: Barkmeijer Stroobos BV/Koninklijke Niestern Sander

- Length x breadth: 134.10 metres x 21.40 metres

- Design speed: 13.5 knots

- Installed power (four dual-fuel generator sets): 4 x 2000 kilowatts

- LNG tank capacity (approximately) 325 cubic metres

- Maximum dredging depth: 37.0 metres

- Hopper capacity: 5900 cubic metres

Carbon Capture on Board

In addition to the use of LNG, the subject of carbon capture attracts increasingly more general attention as a way of meeting emission targets. At the beginning of 2018, the recently graduated Joan van den Akker started at Conoship International as a naval architect. He was able to continue his graduation thesis at TNO on the relatively unexplored subject of onboard carbon capture at Conoship.

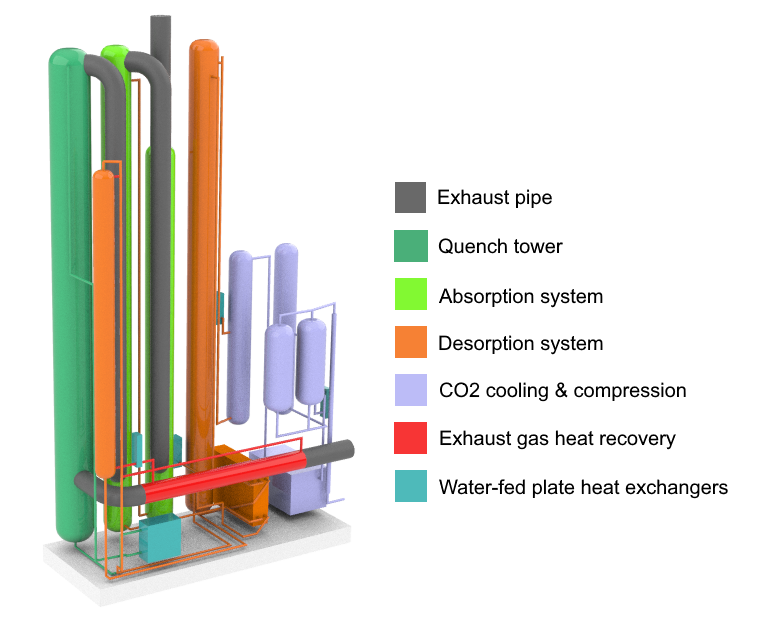

Onboard carbon capture system as considered in the CO2ASTS project (courtesy of MARIKO GmbH/Conoship).

Onboard carbon capture system as considered in the CO2ASTS project (courtesy of MARIKO GmbH/Conoship).

This theme was the subject of a discussion for a new research project. While Van den Akker’s graduation thesis was an initial exploration of the possibilities of onboard carbon capture, this research would focus on the technical and economic feasibility. This would be investigated and tested on the basis of three use cases, including for the Ecodelta.

Two years later, the results of this interregional cooperation project called CO2ASTS, supported by an EU subsidy, were presented at Europort 2019.

Retrofit Best Option

The feasibility study focuses on ship based carbon capture and storage for inland and short sea shipping using LNG as a fuel. The main objective is to gain insight into the main cost drivers and the possibilities for minimising the costs per kilogramme of CO2.

The most important conclusion to be drawn for a vessel such as the Ecodelta is that an onboard carbon capture system through retrofitting has the best adaptability. The use of LNG and the available space on board for the installation are the main factors that support this conclusion. The Ecodelta would even be hydrogen ready to achieve a closed carbon loop.

An onboard carbon capture system through retrofitting has the best adaptability

The actual application of retrofits remains highly dependent on the CAPEX (capital expenditure), although this could be reduced by smart installation solutions. The captured CO2 can today be re-used in the food industry and greenhouses (to increase the growth-rate of tomatoes for example).

LNG Powered Ships Are Ready for Hydrogen Economy

For the future of the “hydrogen economy”, it is expected that the containerised liquified CO2 will be a valuable feedstock for the production of synthetic carbon fuels: when large quantities of hydrogen (H2) will be produced using solar or (excessive) wind energy, synthetic fuels can be produced out of H2 and CO2, like methane (CH4) or methanol (CH3OH). These synthetic fuels can be the “hydrogen-carriers” that can be bunkered in a ship (better than liquid or pressurised H2).

CO2 capture model.

CO2 capture model.

Moreover, liquified synthetic methane CH4 is the same molecule as the main component of LNG (about eighty per cent CH4). It is also liquid at minus 163 degrees Celcius and can be bunkered in exactly the same tank with the same systems as the actual LNG systems. The infrastructure on board and on land will stay the same and the current and developing LNG infrastructure and ships can still be utilised in the hydrogen economy of the future, providing the CO2 is captured and re-used, creating a non-fossil CO2 cycle.

A slightly longer version of this article has also been published in SWZ|Maritime’s November issue. Pictures supplied by Conoship International.