As part of the Fourth Industrial Revolution, smart data analysis and machine learning are used to make shipping and shipbuilding both smarter and safer. This brings out the question: Which tasks do we assign to machines and what role is left for human beings?

In SWZ|Maritime’s January 2021 issue, SWZ editor Annelinde Gerritsen discusses the research, case studies and findings on solutions for the “Fourth Industrial Revolution” as presented by several maritime companies and institutes at the online symposium Smart Ship Technology. This event was hosted by the Royal Institute of Naval Architects (RINA) on 14 and 15 October 2020. Read the full article below.

In SWZ|Maritime’s January 2021 issue, SWZ editor Annelinde Gerritsen discusses the research, case studies and findings on solutions for the “Fourth Industrial Revolution” as presented by several maritime companies and institutes at the online symposium Smart Ship Technology. This event was hosted by the Royal Institute of Naval Architects (RINA) on 14 and 15 October 2020. Read the full article below.

The Fourth Industrial Revolution is described as a revolution in which smart machines can analyse and diagnose issues without the need for human intervention. ‘It is characterised by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres’ [13]. With the use of smart technology, like learning algorithms, machines can take over tasks of humans and process them much faster and more reliably. But the creative process can still only be done by humans, so far…

Potential of technology is widening

In the design of a ship, applications are used for automation of recurring tasks, standardisation of objects or designs, identification of design anomalies, validation of designs, and so on. Standardisation can reduce work time, minimise the use of materials, avoid errors and save costs. Detection of deviations in the data can prevent errors and can avoid a lot of rework or fixing later in the design and building process [1].

Also read: Digital technologies in the maritime domain explained

Artificial intelligence (AI) can be used to take over jobs from humans that require a lot of calculation, memorisation and learning capacity. Autonomous vessels can take over tasks that have to be performed in an unsafe environment. The potential of these technologies is widening, but first we have to make sure they are reliable.

Artificial intelligence (AI) can be used to take over jobs from humans that require a lot of calculation, memorisation and learning capacit

Condition monitoring

In one use case, an online condition monitoring system was introduced where real-life data from sensors on board a tanker ship have been used for the prediction of failure of the cylinders of two diesel generators. Parameters like exhaust gases outlet temperature, cooling fresh water (CFW) inlet pressure, CFW outlet temperature, cooling air temperature, lube oil (LO) inlet pressure, LO inlet temperature and exhaust gas outlet temperature are taken into account in stable operational profiles and weather conditions.

Also read: Dutch navy to apply data science to get to predictive maintenance

The smart system detects the change of the condition of the machinery in real time by utilising the local outlier factor (LOF) algorithm, which detects anomalies in the data.

By combining calculated predictions and real-life data of the behaviour of machinery on board ships, better estimations can be made for maintenance and fuel consumption. This approach allows shipowners and operators to be more in charge of the maintenance schedule, since the maintenance intervals suggested by the manufacturer do not take into account the real condition of the machinery. It also creates room for a more efficient schedule [9].

Real time decision support

Decision support systems are becoming ever more interesting tools due to their high potential of supporting ship operators when deciding on different voyage scenarios. These systems can be used for weather routing, slow steaming and trim and ballast optimisation purposes.

A group of Turkish scientists presented a model for prediction of the real time fuel consumption rate during the voyage, based on an artificial neural network (ANN). By measuring the outputs and comparing them with the predicted ones, the results of the study show that the model can be a reliable base for decision support [12].

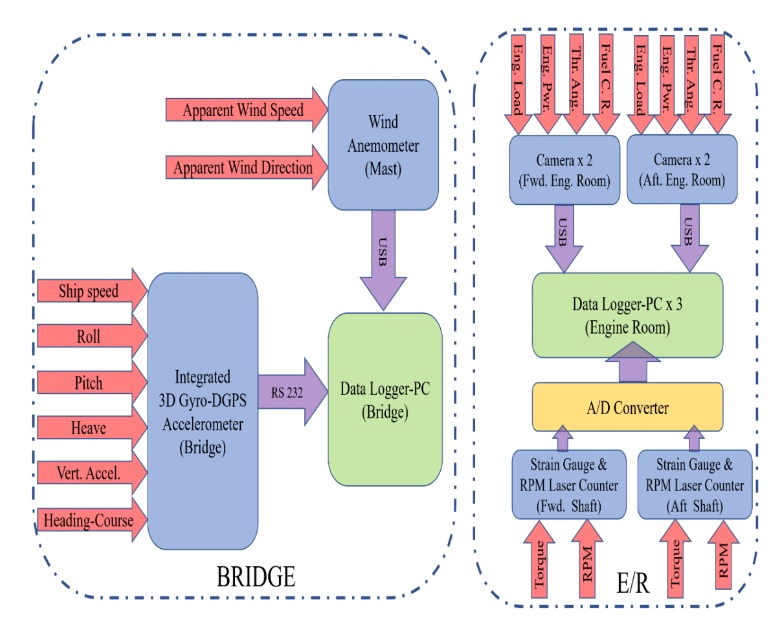

A data acquisition system’s fuel consumption rate prediction [12].

Virtual hull monitoring of a digital twin

In the shipping industry, more and more digital twins are being used, where a digital copy of the ship can provide information for intelligent operational decision support during operation or for predictive maintenance, drydock planning, inspection optimisation, life extension and fleet management [2]. A digital twin is a virtual representation of a product, asset, system or process and is first and foremost a learning system, driven by data that is collected from sensors in real time. The lessons learned provide humans with reliable information to base their decisions on [3].

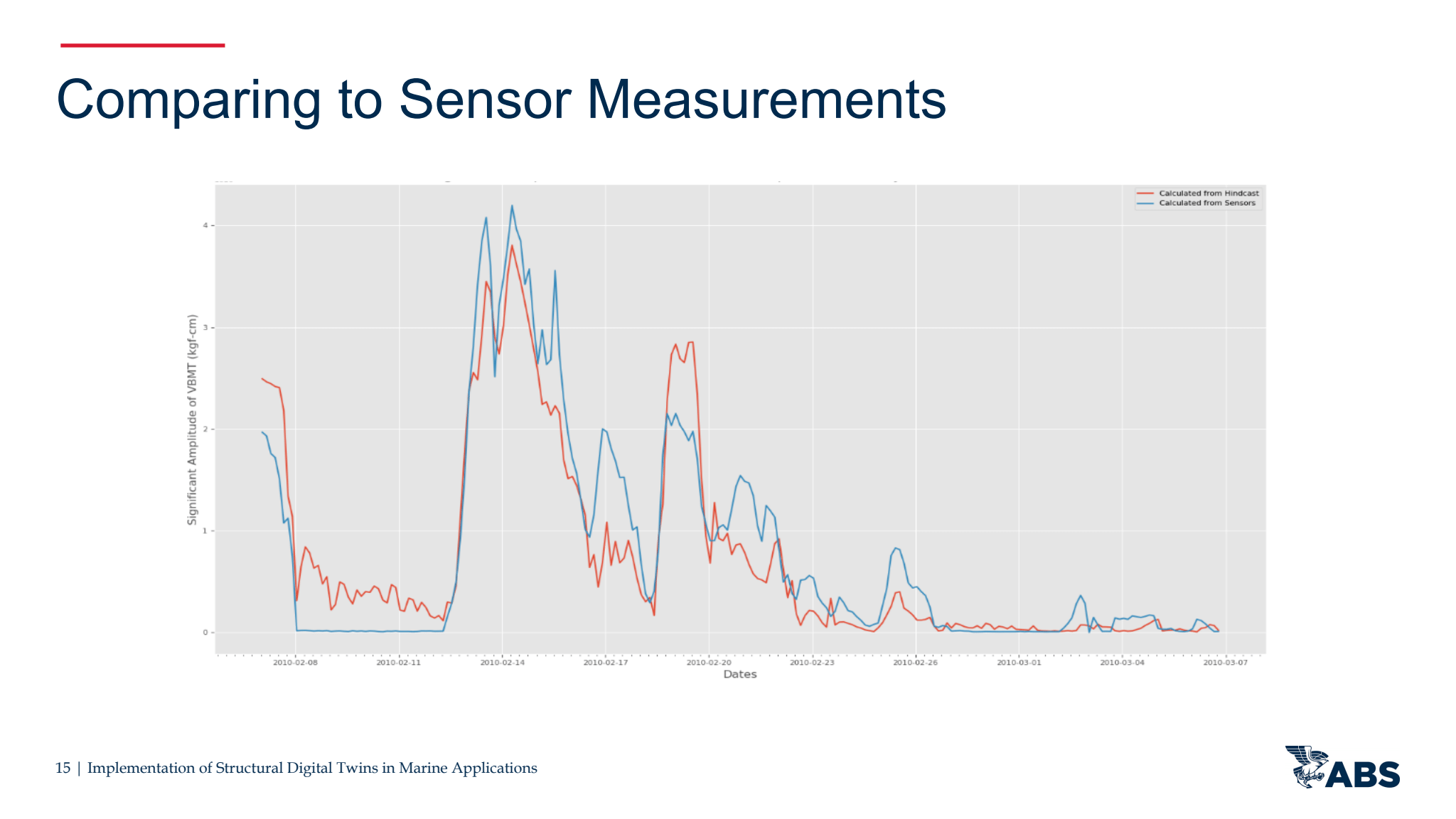

Classification society ABS uses a structural digital twin framework that integrates vessel-specific data such as loading, navigation, environmental conditions, and structural condition for first principlesbased strength and fatigue assessment approaches. Together with publicly available data sets, such as the automatic identification system (AIS) data and weather hindcast data, an operational profile and encountered wave summary were constructed for post-voyage analysis, which also provides fundamental data for future operational and design optimisation. In this approach, no onboard sensors are being used, apart from sensor measurements for validation of the monitored global hull-girder loads [2].

Comparison of hindcast calculations and sensor data of ABS [2].

A cooperation of Australian, Italian and UK scientists are working on data analytics methods and cloud computing resources for remotely monitoring motions and structural responses of a 111-metre high-speed catamaran. In this case, direct measurements on board are being used, in which information about the ship and its environment is not collected from external sources, but from big data produced by sensors on board. Three main areas have been considered for the analyses: evaluating motion comfort through motion sickness incidence (MSI), identifying rainflow cycles for fatigue damage analyses and development of a method for slamming identification.

Also read: AI research to make sea voyages more energy efficient

Big data from the ship’s sensors are processed by a cloud processing solution. This solution facilitated parallel processing of raw data and provided a framework for training various machine learning (ML) and deep learning (DL) algorithms [11].

Safer operations with autonomous vessels

Unmanned vessels like autonomous surface vessels (ASVs) can be more capable of sailing in harsh environmental conditions because no human beings are on board that can be harmed. For example, to improve coastal security and to help minimise manpower cost through remote operation and better performance in any environmental condition, an unmanned surveillance boat was designed for coast guard functions. Together with effective management from shore manoeuvring of the craft in tight waterways can also be performed [5].

The fundamental aspect of any ASV is trajectory prediction and planning. The vessels generate multifarious data from a number of different sensors on board and positioning systems like the AIS. Artificial intelligence techniques and algorithms are then used for self-estimation of operational decisions with respect to its environmental conditions and position [4].

More advanced equipment for monitoring and operation

The design of autonomous and remotely operated vessels requires a different approach because of the risk of collision, grounding, loss of communication, cyber security breaches and the lack of detection of equipment failure that is otherwise noticed by the crew on board. This asks for installation of more advanced equipment for monitoring and operation than on manned craft.

On the other hand, there is no need for space for cabins, a galley, staircases, maintenance envelopes around machinery, air conditioning, et cetera [5].

A design from the Emirates (UAE) shows the required considerations: Stabilised cameras with an uninterrupted 360-degree view, long-range acoustic devices (LRADs) that communicate with the shore control centre (SCC) in real time, a high capacity data link for direct transfer to HDTV, sensor and guidance signals and instrumentation with better communication bandwidth are installed for operation of the craft. In addition, a drone can be used, which is operated from the SCC. An intermediate receiver is installed in the craft to get better access to the drone, thereby resulting in effective surveillance.

Effective sensors are used across the outer hull of the craft to avoid collision with other vessels

Effective sensors are used across the outer hull of the craft to avoid collision with other vessels especially in heavy traffic regions. Automatic fire detectors are mounted and a CO2 fire extinguisher can be used as an advantage due to the absence of people on board. Cyber security is a critical issue for unmanned vessels, therefore all equipment is encrypted to safeguard it from any illegal operation of the craft [5].

Optimal routing in ice conditions

A fundamental challenge in allowing autonomy or decision-support for navigation of ice-covered waters is providing ice severity data that feeds decision-making. There is a wealth of ice data available from various sources. In order to make this data more useful, significant integration is needed to provide an actual near-term forecast and a long-term forecast of ice conditions. This would allow ships’ captains to assess the likely ice conditions along their route and adjust their route and speed accordingly.

This would allow ships’ captains to assess the likely ice conditions along their route and adjust their route and speed accordingly

Satellite-based information, aerial information, land and seabed-based information, forecast tools and information, historical data and data from risk assessment tools are being aggregated in a proposed framework by the National Research Council of Canada. This results in a regional map of forecast ice severity based on a vessel-specific risk assessment model, which can predict regional ice pressure with accuracy. This would provide a decision-making tool for ship operators and autonomous navigation systems [8].

Data from sensors that measure the ice surrounding the ship, which can build a local map of ice severity and measure the interaction between the ship and the ice, provide calibration and more accurate information. This can be used to assess local ice severity and to decide how the ship will navigate the ice while avoiding damage to the ship or becoming beset.

Typically, this assessment is made by the officer in charge with significant levels of experience needed to assess and navigate severe ice conditions. A challenge in allowing autonomy or decision-support for navigation of ice-covered waters is providing ice severity data that feeds decision-making algorithms [7].

Machine and human learning

Big data gives us the opportunity to learn. The more data is processed, the more a machine is capable to learn and predict from the patterns. The interpretation of these patterns gives human beings the opportunity to take an extra step in learning and evolve in a new industrial revolution.

Key to this development is the availability of data. The more data is shared and integrated, the more accurate and precise the algorithms and learning mechanisms will be. On the other hand, data can be confidential as it may be the specialised knowledge of a company. Therefore, it is important to indicate which data are confidential and which are not.

Cyber security soon requires an integrated approach by both industry and regulators

A new issue to be addressed is cyber security, since the data-driven operations are vulnerable to cyber attacks. We have to keep these systems secure, whether at sea, ashore or in the supply chain. An integrated approach by the maritime industry together with regulators in the US, EU, and across the world is needed soon to address this problem [10].

The developments are promising, but a big role still remains for human beings in this process. Detected anomalies still need to be judged by humans and unforeseen circumstances ask for the creativity of the human mind. For example, human examination of the satellite data of ice conditions is currently still needed, but tools may be developed that allow automation.

Modern communication technologies are advancing at an unprecedented pace, but there are still challenges associated with providing high-bandwidth, reliable data transfer to ships navigating around the globe. If ships are to rely on data from outside sources for navigational decision making, the delivery of this data must be very robust [8].