Mitsui O.S.K. Lines, Japan Hamworthy and Akishima Laboratories are conducting research and development on Propeller Boss Cap Fins and an energy-saving rudder with bulb fins. Their research shows an energy saving effect of more than 5 per cent with this type of rudder alone.

In the development of the energy-saving rudder with bulb fins, the companies have enhanced the energy-saving performance and improved horsepower by taking advantage of the steering effect of the rudder of JHC, a specialised manufacturer of high lift rudder such as schilling rudder. The features of the developed rudder are as follows:

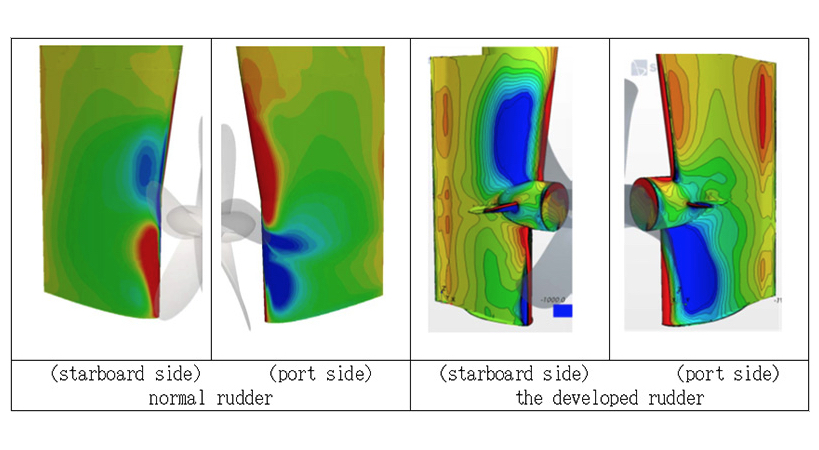

- In order to recover the swirling flow of the propeller, the reaction shape is designed as a high thrust blade section and the rudder horn is also twisted and integrated so as to increase thrust due to the negative pressure on the rudder.

- By reducing the size of the end plate under the rudder, the resistance is reduced and the propeller swirl flow is also blocked.

- The large central bulb has a flat front surface to reduce the propeller inflow speed and improve propeller efficiency.

A Japan Bulk Carrier (JBC) hull was used, which is open to the public as a general large-sized hull and widely used in various research and development. Generally, it is difficult to improve the horsepower by 4 per cent or more with a normal reaction rudder. However, with the developed rudder, Computational Fluid Dynamics (CFD) showed a 5.7 per cent improvement in horsepower and a self-propulsion test in a large towing tank confirmed 5.2 per cent improvement.

The developed rudder has been applied to the slender ship types as well, and an energy-saving effect of 4.4 per cent has been confirmed by CFD. In the future, the companies plan to conduct a large towing tank test after performing optimisation work. They are also aiming for a synergistic effect with the torque reduction effect of Propeller Boss Cap Fins for future installation on actual ships. The developed rudder has been patented.